Threaded Inserts for Plastics

MW Components offers a wide range of threaded inserts designed specifically for plastics. Styles include chevron, tapered, expansion, press-in, mold-in, and symmetrical threaded inserts. Flanged options are also available.

- Large inventory with next-day delivery for in-stock parts. Free samples available.

- Rapid turnaround times for custom solutions with our quick turn service.

Shop Threaded Inserts Online

Explore our extensive catalog of threaded inserts and filter by style, material, standard and metric sizes, finish, and more to customize your selection. In-stock orders are typically shipped out within 24 hours.

Get Custom Threaded Inserts Fast

We manufacture custom threaded inserts to your specifications, with precise engineering and quick delivery. Our team works with you every step of the way to turn your ideas into reality.

- Design & Engineering Support

- Prototyping to Full-Scale Production

- Fast Turnaround Times

- Expedited Delivery Options Through Our Quick Turn Service

Threaded Insert Styles & Installation Methods

We offer a wide range of styles and materials with various installation methods, such as ultrasonic, thermal/heat, or press-in techniques. Whether you require standard parts or customized solutions, we offer rapid turnaround times and expert customization services to meet your specific needs.

Proper installation practices are crucial for ensuring optimal performance and durability of threaded inserts. Check out our threaded insert installation guide to help you seamlessly install our products into your plastic assemblies.

-

- Used in ultrasonic and thermal applications for thermoplastic or structural foam.

- Features unique “knuckle knurls” that reduce residual stress and increase strength.

- Tapered design reduces installation time, improving alignment accuracy.

Installation Method: Ultrasonic, Thermal/Heat & Mold-In

Insert Series: H Series

-

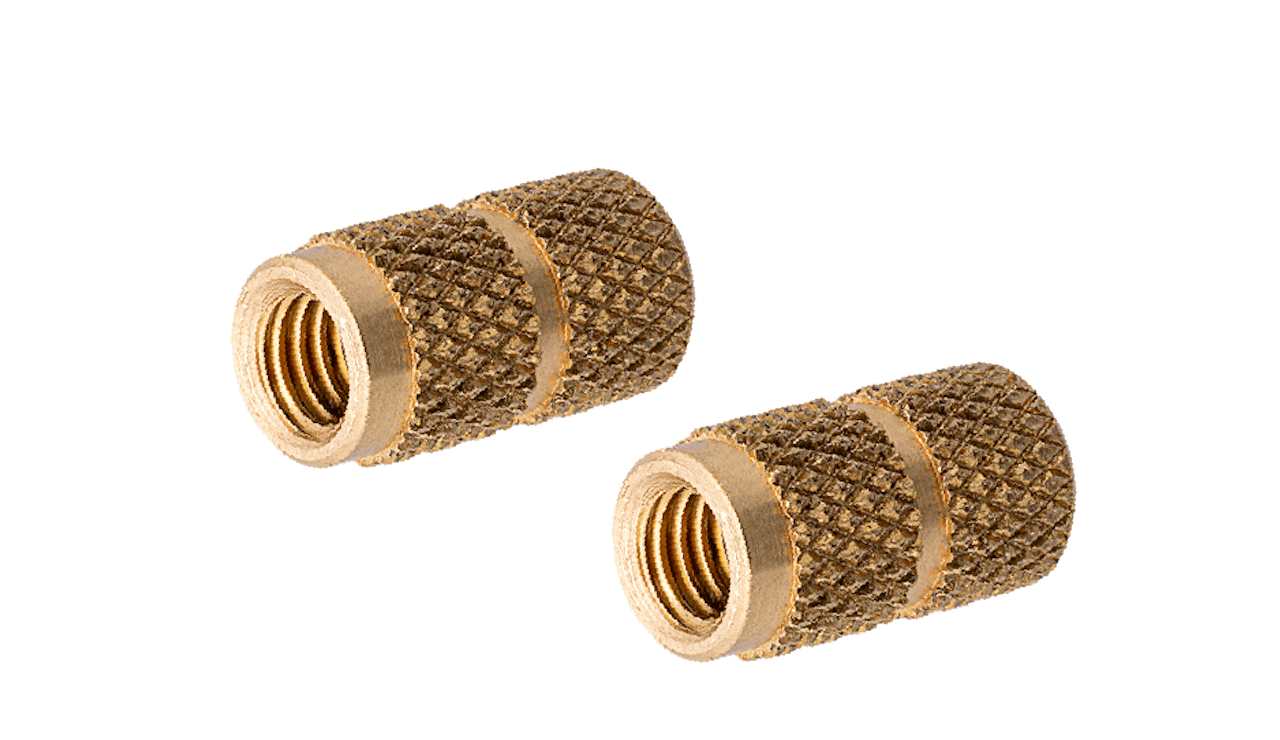

- Designed for straight holes using ultrasonic or thermal processes.

- Features dual bands of sharp diagonal knurls with varying diameters for superior gripping power.

- Includes a lead-in pilot diameter for precise perpendicular alignment during installation.

Installation Method: Ultrasonic, Thermal/Heat & Mold-In

Insert Series: C Series

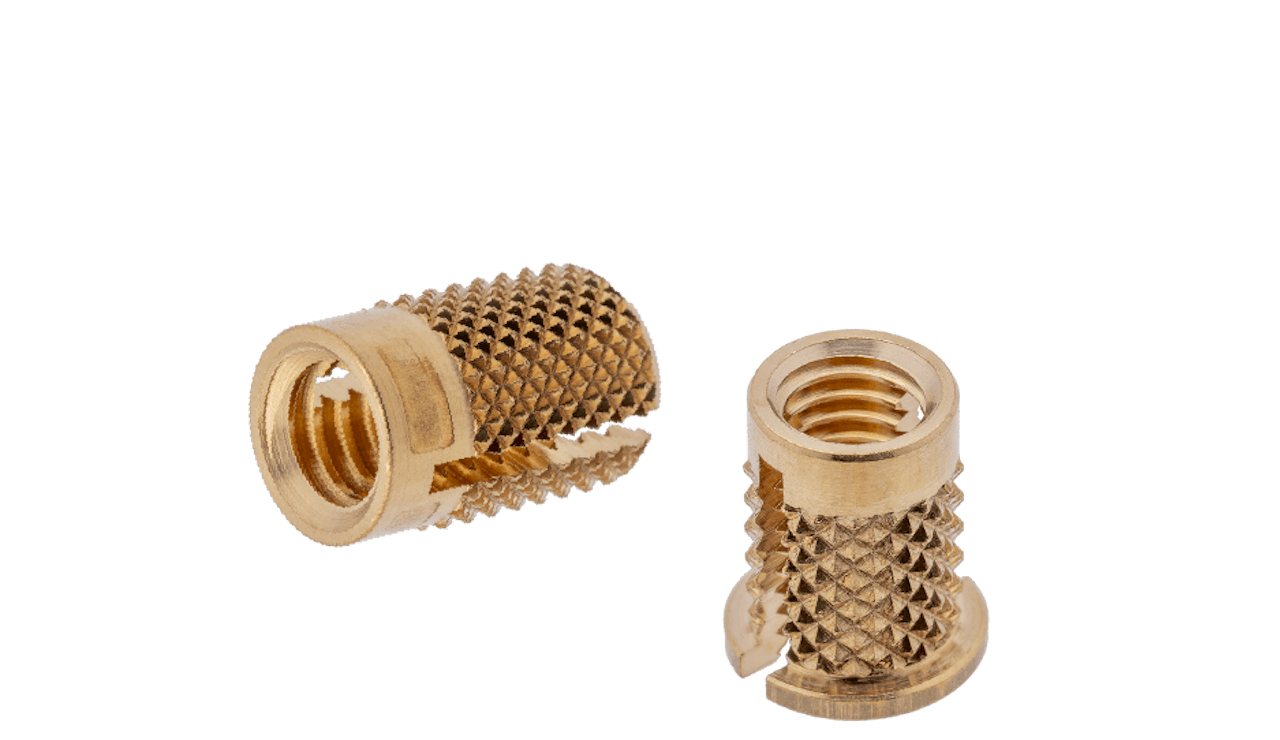

-

- Features a flange designed to enhance load-bearing capability in weaker plastics.

- Flange offers a substantial contact area suitable for electrical connections.

- Ideal for reverse-entry applications, providing outstanding pull-out strengths.

Installation Method: Ultrasonic, Thermal/Heat & Mold-In

Insert Series: HC Series

-

- For fast, high-volume applications install without orientation using ultrasonic or thermal equipment.

- Designed for straight holes, ideal for thin-wall applications with minimal stress on part walls.

Installation Method: Ultrasonic*, Thermal/Heat & Mold-In

Insert Series: S Series

-

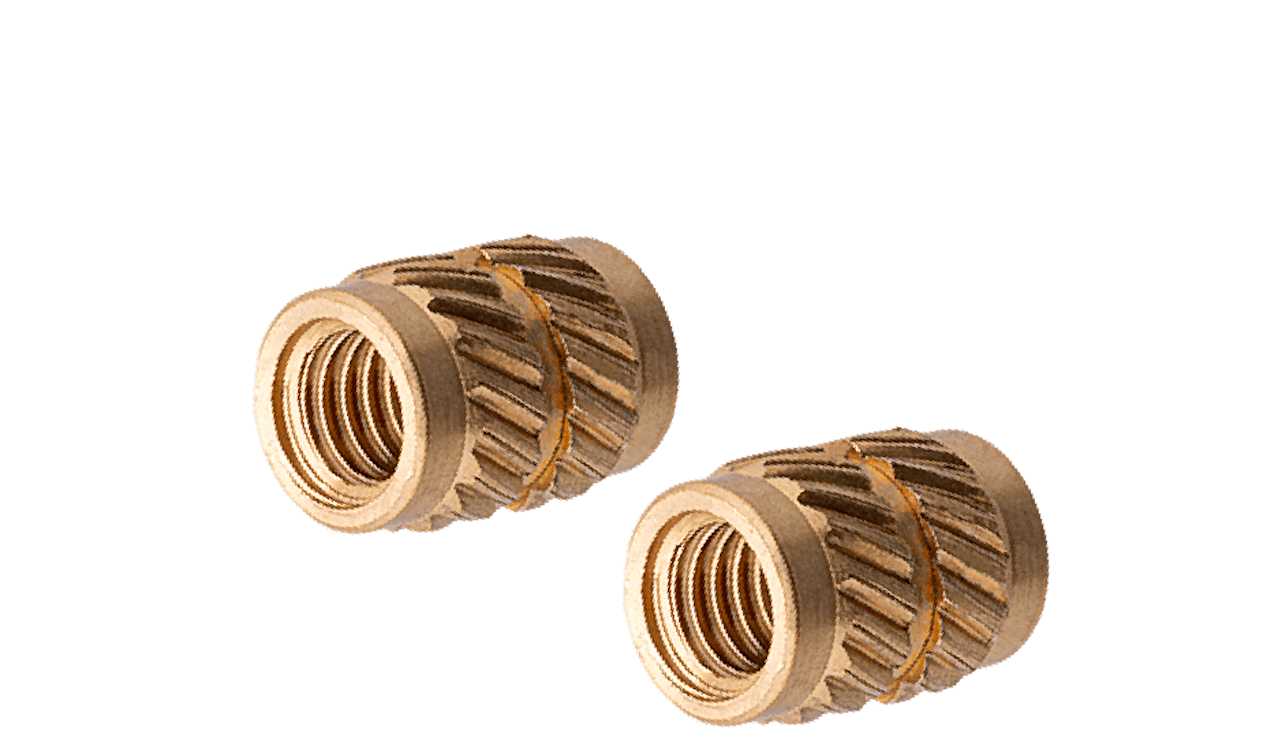

- Provides strong holding without ultrasonic or heat equipment, ideal for thermoset or hard plastics.

- Quick alignment with the pilot end during installation.

- Easily install in hard or thermoset plastics without heat or special tools.

- Three bands of helical knurls ensure deep penetration and secure locking, offering excellent torque-out resistance.

Installation Method: Press-In, Ultrasonic*, Thermal/Heat & Mold-In

Insert Series: P & HP Series

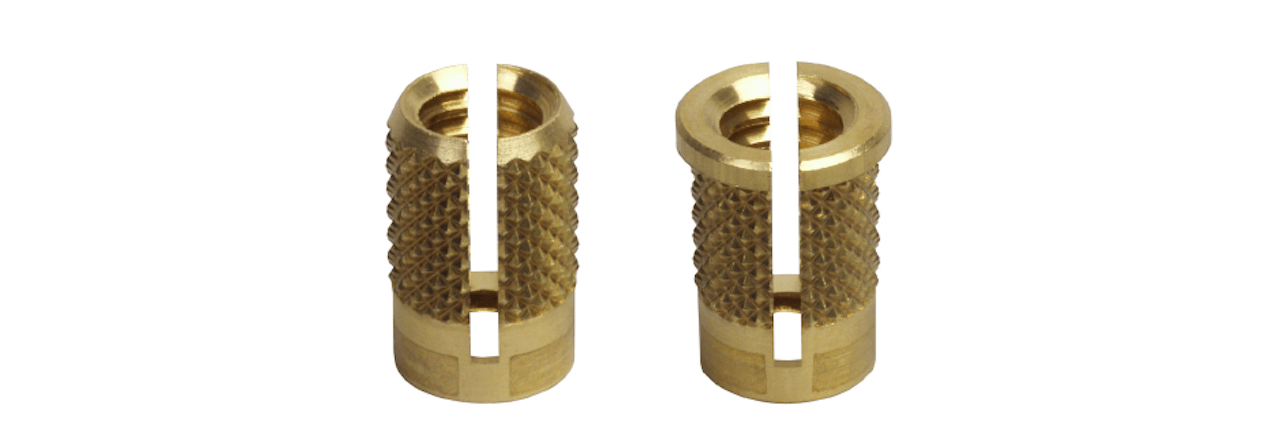

-

- Designed for creating strong, usable threads in thermoset and other hard plastics.

- Inserts are pressed into the plastic and expand upon screw installation.

- Sharp diamond knurls ensure secure anchoring within the plastic.

- Available options include inserts with or without a flange for varied applications.

Installation Method: Press-In

Insert Series: E & HE Series

-

- Designed for molding into plastics, rubber, and ceramics.

- Diamond knurling offers high resistance to tensile pull and rotational torque loads.

- Closed bottom and controlled minor diameter ensure accurate positioning on core pins.

- Closed-end bottom design prevents plastic flow into the threads, maintaining integrity.

Installation Method: Mold-In

Insert Series: MC Series

-

- Designed for molding into plastic components during the molding cycle.

- Features aggressive knurling and undercuts to resist rotational and tensile pull loads.

- Closed bottom (blind thread) design prevents plastic flow into threads.

Installation Method: Mold-In

Insert Series: MB Series

-

- Designed for molding into plastics, rubber, and ceramics.

- Features aggressive diamond knurling for high resistance to tensile pull and rotational torque loads.

- Controlled minor diameter ensures accurate positioning on core pins during molding.

Installation Method: Mold-In

Insert Series: MT Series

-

- Versatile inserts designed for a wide range of applications.

- Commonly used for stacking printed circuit boards or as threaded spacers.

- Can be molded into plastic components for integrated assembly.

Installation Method: Mold-In

Insert Series: KS Series

-

- Available in H or C Series body designs.

- Saves on production costs and functioning as electrical contacts or screw replacements.

- Adjustable thread lengths to meet specific requirements.

- Special studs without threads can be used as axles, pivots, pins, or solder terminals as needed.

Installation Method: Ultrasonic, Thermal/Heat & Mold-In

Insert Series: SH & SC Series

-

- Unthreaded spacers (bushings) used to reinforce plastics under compression loads.

- Compression loads occur during bolt and screw fastening in assembly processes.

- Compression limiters can be customized for various installation methods.

Installation Method: Ultrasonic, Thermal/Heat, Mold-In & Press-In

Insert Series: CL Series

Threaded Insert Capabilities & Services to Support Your Projects

We offer a wide range of threaded inserts that can be customized to meet your specific requirements and applications. Our threaded inserts are made from various materials and are available in different thread sizes and styles. We provide services, such as machining, finishing, and secondary operations, to ensure the highest standards of precision and quality. To meet your project timelines, our Quick Turn Service delivers customized threaded inserts with options from 1 day to 3 weeks.

Manufacturing Services

In addition to standard engineering and manufacturing services, we offer various optional services to assist you in developing the best product for your application or end-use.

- CAD Modeling

- Prototyping

- Grinding

- Tooling & More

CAD files for stock and standard threaded inserts are available for download in our Shop Online section.

Value-Added Services

Our range of enhanced services is designed to streamline your operations and optimize production efficiency. These services include:

- Sorting Capabilities: We offer 100% inspection on select threaded inserts, enhancing efficiency and productivity while reducing inspection costs.

- Scheduled Shipments: Streamline inventory management by scheduling shipments based on your production schedule. Place bulk orders and get deliveries when needed, saving costs and improving workflow efficiency.

Contact us today to discuss your project requirements.

Finishes and Platings

We offer various additional processes and finishes, to ensure your threaded inserts meet your desired specifications. Additional processes include:

- Heat Treating

- In-House Plating

- Knurling

- Secondary Operations & More

Contact us about our in-house plating service, offering quick turnaround times. We can plate and ship stock plating parts in as little as 3 days.

Quality Materials

We offer a wide range of standard and specialty materials, ensuring compatibility with various environments and performance requirements. Brass threaded inserts are popular due to their corrosion resistance, electrical conductivity, longevity, cost-effectiveness, and versatility across industries and applications.

- Stainless Steel

- Aluminum

- Brass

- Copper & More

Contact us for custom quote information if you require custom materials.

Quality Certifications & Standards

At MW, we pride ourselves on creating quality products that meet or exceed industry standards. Not only do our facilities perform rigorous quality assurance testing to your specified ranges, but we also maintain several key certifications to ensure that only the best products are shipped to you.

Threaded Insert Tools & Resources

Additional Information on Threaded Inserts

Heat Set Threaded Inserts

We provide a comprehensive range of threaded inserts designed for ultrasonic or heat installation into thermoplastics or structural foam materials. Our heat-set threaded inserts offer high-performance strength and cost-effective advantages when installed into tapered or straight plastic molded holes. Key features include:

- Lead-in pilot diameter for precise alignment before installation.

- Available in two lengths for enhanced assembly strength.

- Materials include 360 Brass, Aluminum, and 303 Stainless Steel for various properties like conductivity, lightweight, and corrosion resistance.

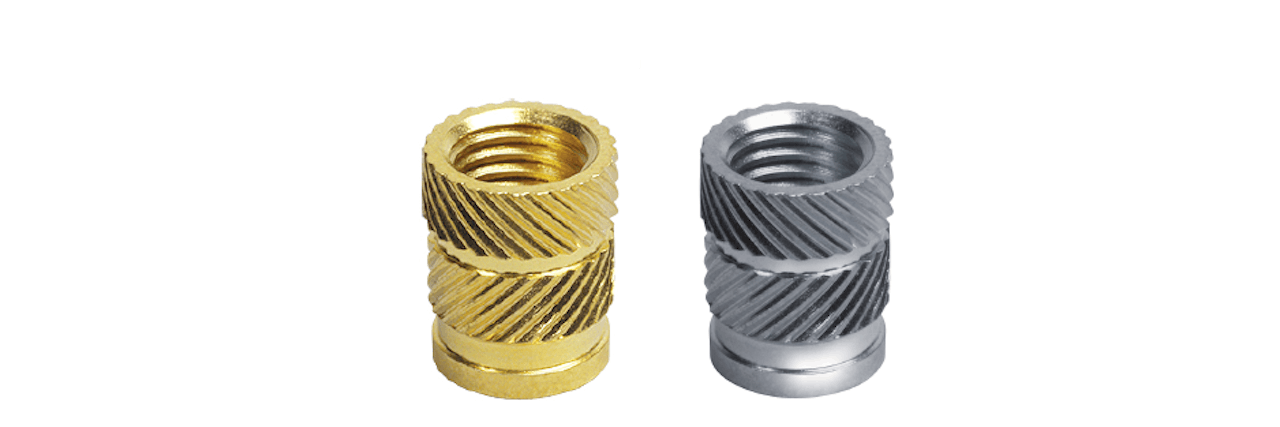

Knurled Threaded Inserts

MW Components provides knurled threaded inserts designed for ultrasonic, heat, or press-in installations into thermoplastic and structural foam materials. The outer body knurl designs provide excellent torque resistance and the undercut channels deliver optimum pull-out strength.

The plastic area surrounding molded hole softens when heated during insert installation, then cools to re-solidify which provides a tight grip around the insert’s knurls and undercuts sections to ensure strong torque and pull-out resistance.

Offered in a broad range of both Metric and Imperial thread sizes, our knurled threaded inserts are available in 2-3 different lengths.

Stainless Steel Threaded Inserts for Plastics

MW Components offers stainless steel threaded inserts for plastics in various styles and sizes, featuring:

- Manufactured from Stainless Alloy 303 and passivated per QQ-P-35 for enhanced corrosion resistance.

- Suitable for highly corrosive and sanitary environments like food and beverage industries, medical settings, marine applications, and integrated circuit manufacturing.

- Serve as an alternative to materials requiring expensive secondary plating operations.

- Lead-free option for threaded inserts used in diverse industries.

Brass Threaded Inserts for Plastics

MW Components provides a range of brass threaded inserts for plastics, available in diverse styles and sizes:

- Designed to offer durability and reliability in various applications.

- Ideal for use in industries requiring corrosion resistance and electrical conductivity.

- Suitable for applications in electronics, automotive, aerospace, and more.

- Offer a cost-effective alternative to materials requiring additional plating operations.